In the IoT "identification family," Radio Frequency Identification (RFID) tags stand as the undisputed "mainstay," which are divided into two major categories ——: active and passive tags. Many people wonder: What's the real difference between these two types of tags? The core distinction boils down to one thing: where the energy comes from. This difference directly determines their performance, cost, and application scenarios. Today, we'll break down the key differences between them in plain terms.

I. The most fundamental difference: the way energy is supplied

The tag has to work, and it can't do that without an energy-driven chip and an antenna —— which is the core dividing line between them, period.

Unlabeled: The "Minimalist" of "Borrowing Electricity"

The biggest feature of a passive tag (also called a passive tag) is that it has no built-in battery. It gets its energy entirely "borrowed" from the reader:

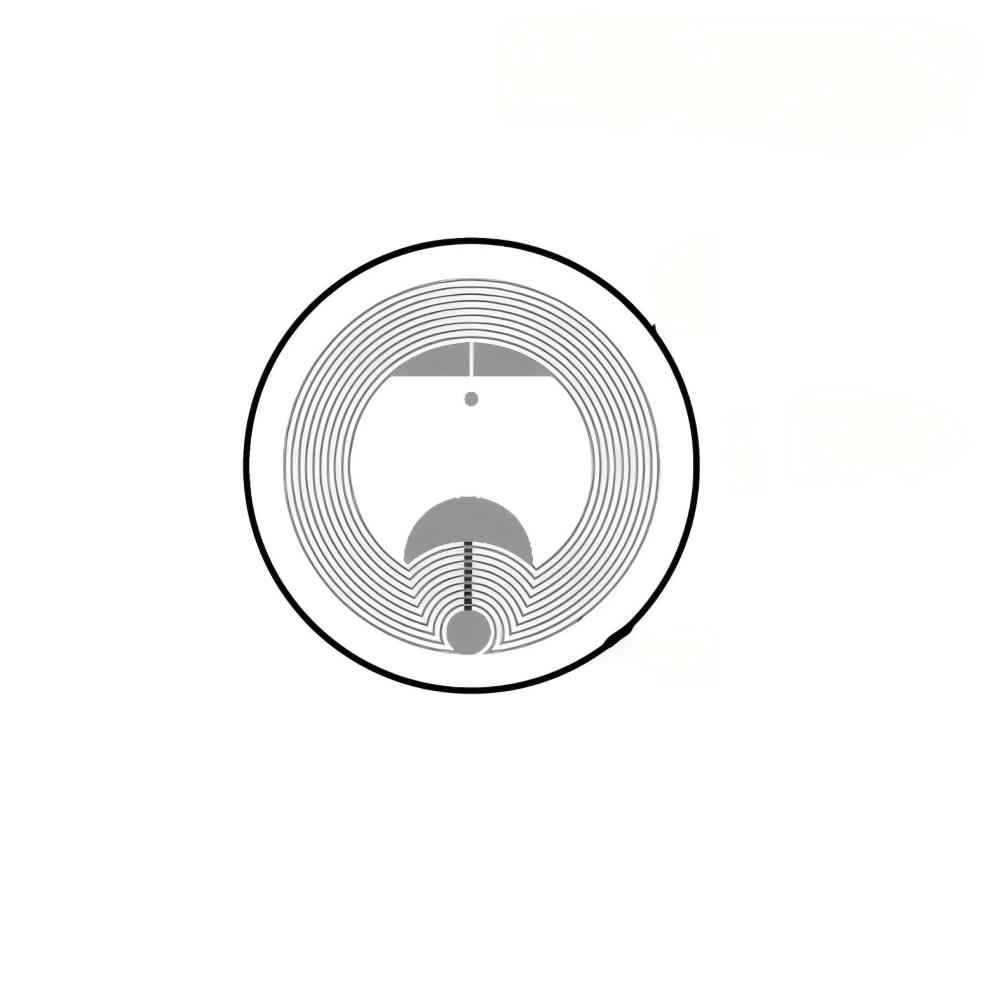

When a reader emits radio frequency (RF) electromagnetic waves, the tag's antenna converts part of this energy into electrical power through either "electromagnetic induction" or "backscatter coupling," powering its internal chip. Once activated, the chip transmits stored data (such as product codes or asset IDs) back to the reader via reflected waves —— essentially "feeding itself" through the reader's signal before retrieving the information.

The design makes it extremely simple: just an antenna and a chip, less than 0.1mm thick, and can even be attached to a product like a sticker.

Active tag: "Active announcer" with built-in battery

An active tag (also called an active tag) is "self-contained" —— with a replaceable or non-replaceable battery that continuously powers the chip and antenna.

Unlike traditional readers that rely on external power, this device actively transmits wireless signals to the reader (similar to how phones send messages). With its own power source, it delivers stronger signals and longer transmission ranges. It also proactively reports status updates like location changes or remaining battery, essentially acting as a self-powered beacon that actively communicates with the reader.

But batteries also make it larger (usually the size of a lighter or business card) and much heavier than passive tags.

II. Performance comparison: From distance to cost, the difference is clear at a glance

The difference in energy supply, like the "butterfly effect", affects all the key properties of both.

Comparative dimensions | Unlabeled tags | Source Label |

Read distance | Usually 0.1 m ~10 m (special design can reach 40 m) | Common 10 m ~200 m (industrial grade further) |

Prime cost | Single 0.1 yuan ~2 yuan (batch lower to a few cents) | Single 10 yuan ~100 yuan (the better the battery, the more expensive) |

Life time | More than 10 years (no battery loss) | 3~10 years (depending on battery capacity and usage frequency) |

Data storage | Small (usually 128~1024 bits, store basic information) | Large (can reach several KB, storage status, location and other details) |

Environmental suitability | Fear of metal/liquid (signal is easily attenuated) | Strong anti-interference (suitable for complex environment) |

Mobile recognition capability | Slow (highest support 50 km/h) | Fast (support 200 km/h high speed recognition) |

For example, supermarket product labels are passive —— and cost-effective (a few cents each), taking up minimal space on packaging. They can be read by scanners within 10 centimeters during checkout. In contrast, logistics companies use active tags —— for tracking containers. As containers move at high speeds (hundreds of kilometers per hour) in ports, they need to be detected from over 100 meters away and their positions must be recorded during transportation – all requiring energy from batteries.

III. Application scenarios: There is no "better", only "more appropriate"

Because of the significant performance differences, active and passive tags hardly "compete for work", but each covers a different field ——. Selecting the right tags can make the Internet of Things system both useful and cost-effective.

Unlabeled: Suitable for "low cost, short distance, large volume" scenarios

• Retail/catering: product price tags, anti-counterfeiting labels (such as traceability labels for cosmetics and drugs), which must be printed hundreds of thousands of times at a time with low cost;

• Access control/transportation card: subway card, community access card, can be used by approaching the reader (within 10 cm), no need to change the battery;

• Library/Archive management: Book tags, file tags, can be read by the reader (within 1 meter) during inventory, no need to install batteries for each book.

Active tags: suitable for "high value, long distance, dynamic tracking" scenarios

• Logistics/supply chain: Containers, trucks, high-value goods (e.g., auto parts, medical devices) that need to be identified from tens of meters away and tracked in real time;

• Industrial production: Large equipment in the factory (such as machine tools, robotic arms) need to be positioned 50 meters away when moving in the workshop to avoid collision;

• Special environment: personnel positioning tags in mines, pipeline monitoring tags in oil fields, complex environment (metal, dust), strong signal is required, and batteries need to be used for several years without replacement.

There is also a "moderate solution" called semi-active tags ——, which have a small battery that doesn't operate normally but activates only when receiving signals from readers. These tags can be up to 20 meters farther than passive tags and are more cost-effective than active tags, making them suitable for asset leasing scenarios like shared power banks or equipment rentals.

IV. Future trends: boundaries are blurred, but core differences remain

With technological advancements, passive tags now achieve read ranges of up to 40 meters through energy harvesting systems (acquiring power from light or vibrations), nearly matching the performance of early active tags. Meanwhile, active tags are evolving with low-power designs that extend battery life to 10 years. However, regardless of how technology evolves, the fundamental difference —— "whether they come with built-in batteries" —— remains unchanged:

• Passive tags are preferred whenever large quantities and low cost applications are required (e.g., labeling every item);

• Active tags are still irreplaceable for long distance, dynamic tracking (such as tracking trucks and containers).

In the future, we may see more "hybrid solutions": for example, a logistics package with a passive tag to record the details of the goods (low cost) and an active tag to track the entire transport route (long distance), which together make the tracking more accurate.

The essence boils down to this: Passive tags "work by borrowing power, saving both money and hassle," while active tags "carry their own batteries, handling heavy-duty tasks." They aren't competitors but partners in the IoT ecosystem—— Thanks to these two types of tags, we enjoy the convenience of "supermarket checkout express" and the reassurance of "precise parcel tracking." Next time you spot those ubiquitous tags around you, why not ponder: Are they "borrowing electricity" or "carrying their own power"?