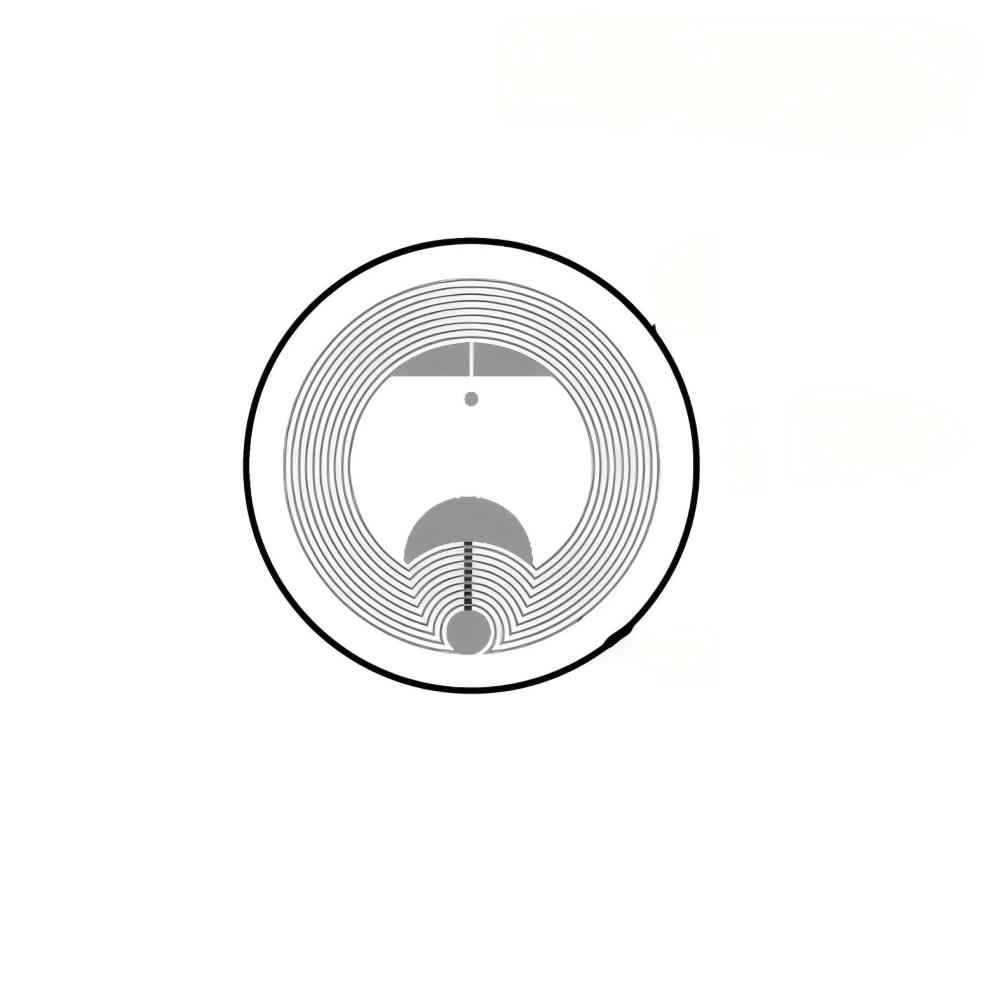

In today's era of rapid IoT development, Radio Frequency Identification (RFID) technology, as the core infrastructure, is deeply penetrating various industries. An RFID system consists of three key components: readers, antennas, and electronic tags. The performance of these tags, which serve as data carriers, directly determines the system's reliability and applicability. Based on operating frequencies, RFID tags are categorized into low-frequency (LF), high-frequency (HF), ultra-high frequency (UHF), and microwave (MW) types. Furthermore, specialized tag products have emerged to meet diverse application scenarios and functional requirements.

I. Analysis of common RFID electronic tags and their characteristics

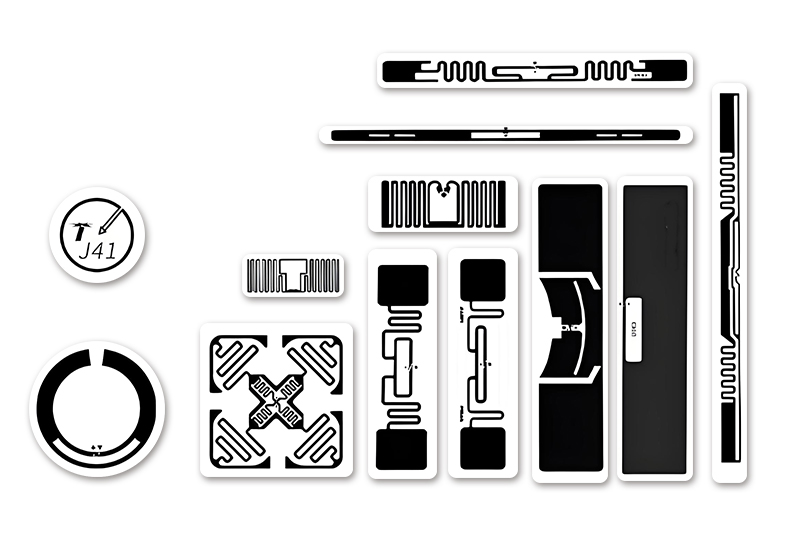

1. UHF adhesive electronic tags

Product Features: The UHF adhesive electronic tag utilizes flexible substrate with a strong adhesive layer on the back, enabling direct application to various surfaces. Operating within the 860-960MHz frequency range, it delivers exceptional performance: -Maximum reading distance exceeds 10 meters-Compact design minimizes visual impact on items-Cost-effective for mass production-Customizable printing of logos or barcodes for brand enhancement

Typical application scenarios:

(1) Retail management: realize precision management of clothing, shoes, hats, electronic products and other single items, improve inventory and sales settlement efficiency.

(2) Logistics storage: used for carton, pallet and other logistics unit identification, to facilitate rapid sorting and tracking of goods.

(3) Document management: track important files, contracts and other documents to prevent loss and wrong placement.

(4) Asset management: applicable to the information management of non-metallic items such as office equipment and instruments.

2. Flexible anti-metal electronic tags

Product Features: Flexible anti-metal electronic tags utilize specialized anti-metal materials as their base, effectively addressing the performance degradation issues common in conventional tags when applied to metal surfaces. Engineered specifically for metallic environments, these tags maintain flexible and bendable characteristics while being 1-3mm thick, offering exceptional heat resistance and corrosion resistance.

Typical application scenarios:

(1) Metal container management: used for chemical barrels, gas cylinders and other metal containers identification and tracking.

(2) Equipment asset management: applicable to the whole life cycle management of metal shell instruments and equipment.

(3) Automotive parts management: precise traceability of key automotive parts such as engine parts and transmission.

(4) Power equipment management: realize the efficient operation and maintenance of power equipment such as transformers and distribution cabinets.

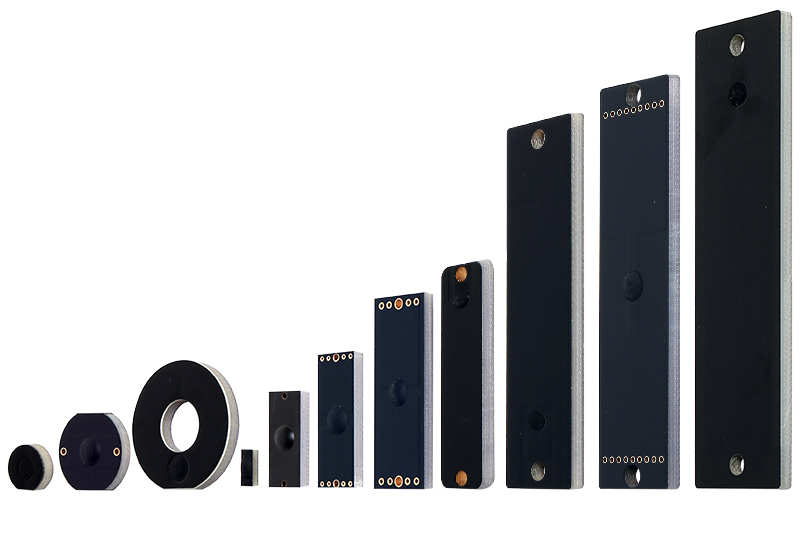

3. PCB anti-metal electronic tags

Product Features: PCB-based anti-metallization electronic tags utilize printed circuit boards (PCBs) as their base material, delivering exceptional anti-metallization performance and stability. The rigid structure provides robust mechanical strength, enabling operation in extreme environments ranging from-40℃ to 85℃. These tags ensure stable and reliable reading performance while supporting customizable designs for various dimensions and shapes.

Typical application scenarios:

(1) Industrial equipment management: suitable for intelligent management of industrial assets such as machine tools and production line equipment.

(2) Power and telecommunication: used for identification and monitoring of base station equipment and power facilities.

(3) Military equipment: meet the high precision identification requirements of weapon systems and logistics equipment.

(4) Outdoor assets: can be used for long-term monitoring of outdoor scenarios such as transportation facilities and municipal equipment.

4. ABS anti-metal electronic tags

Product Features: The ABS Anti-Metal Electronic Tag features an engineering-grade ABS housing that combines exceptional anti-metal properties with robust protection. With IP67-rated waterproof and dustproof capabilities, it withstands impacts and vibrations, making it ideal for harsh industrial environments. The device offers flexible installation options including screw fastening and adhesive bonding.

Typical application scenarios:

(1) Construction machinery management: used for the whole process management of excavators, cranes and other large construction machinery.

(2) Container management: realize efficient tracking and scheduling of sea and railway containers.

(3) Oil and gas industry: suitable for the identification and inspection of oil and gas facilities such as pipelines and valves.

(4) Outdoor asset management: can effectively supervise outdoor assets such as traffic signs and street lights.

5. UHF zip-tie RFID

Product Features: The UHF Zip-Tie RFID Tag innovatively combines an RFID chip with a zip-tie structure, enabling both secure one-time attachment and identification functions. Featuring easy installation and tamper-resistant design, this product ensures high security for cylindrical objects. With excellent weather resistance, it maintains long service life even in outdoor environments.

Typical application scenarios:

(1) Power inspection: used for identification and inspection management of power facilities such as cables and electricity meters.

(2) Gas management: realize accurate monitoring of gas pipelines, gas meters and other gas equipment.

(3) Forestry management: can be used as an effective tool for tree identification and tracking.

(4) Animal management: It can be used as an alternative to livestock ear tags for animal identification and health monitoring.

II. Outlook of RFID Technology Development Trend

With the continuous evolution of Internet of Things technology, RFID electronic tags show the following development trends:

1. Miniaturization: Develop smaller size of label products to adapt to more diversified application scenarios.

2. Intelligence: Integrated sensor function to realize real-time monitoring of temperature, humidity and other environmental parameters.

3. Low cost: Through large-scale production and technological innovation, the cost of labels is continuously reduced.

4. reen environmental protection: increase the application of degradable materials to reduce the impact of e-waste on the environment.

5. Multi-functional integration: promote the integration with QR code, NFC and other technologies to achieve complementary and collaborative applications.

III. CONCLUSION

RFID electronic tags serve as a vital bridge between the physical and digital realms. Their diverse design solutions effectively meet identification and management needs across various industries and application scenarios. From UHF adhesive tags to anti-metallite tags, and specialized zip tag solutions, this diversified product portfolio lays a solid foundation for digital transformation in multiple sectors. With continuous technological breakthroughs and expanding application scenarios, RFID technology will play an increasingly vital role in the IoT era, accelerating industry-wide progress toward intelligent and efficient operations. When selecting RFID tags, enterprises should comprehensively evaluate factors including operational environments, read range, installation methods, and budget constraints to identify the most suitable solutions tailored to their specific business requirements.